It was interesting to look at papyrus and scrolls written on

animal skin before looking at later developed techniques for making paper. We

found papyrus to be more brittle, and both papyrus and vellum are more easily

rolled up instead of folded. As far as making paper goes, I was surprised to learn that it was often produced from rags

that were broken down and that child labor was commonly used to fulfill this

task. Of particular interest to

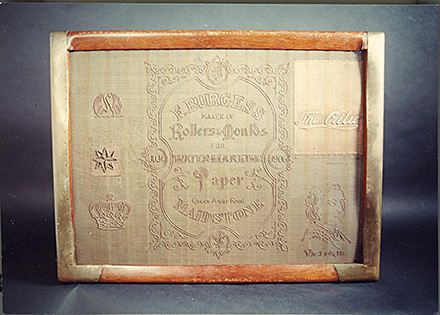

me were some new words I learned. For example, the mould and deckle are used in

the papermaking process. The mould is a wire screen used to transfer and shape some of the water and fiber mixture from the vat. The deckle is the removable frame that surrounds the

mould.

Papermaking is usually a three-man process. It includes a vatman, a coucher, and a felt man. The toughest job belongs to the vatman who may work for years to develop his skill for dipping the mould into the vat. Next the paper is passed to the coucher who removes it from the mould and sandwiches it between felt. After more water is removed and it is further compacted, the felt man removes the paper from the felt and replaces it with dry felt. This process was like a forerunner for the assembly line!

Papermaking is usually a three-man process. It includes a vatman, a coucher, and a felt man. The toughest job belongs to the vatman who may work for years to develop his skill for dipping the mould into the vat. Next the paper is passed to the coucher who removes it from the mould and sandwiches it between felt. After more water is removed and it is further compacted, the felt man removes the paper from the felt and replaces it with dry felt. This process was like a forerunner for the assembly line! You can really tell a lot by closely looking at the paper. If the paper has a watermark, you may be able to easily determine when and where it was made. Putting paper up to the light allows us to see some other features. We may see lines

caused by the wires on the mould, or

vatman’s tears, which are water drops from the vatman’s arms, or even more distinct blemishes like thumbprints. Hopefully the paper we make next week will not expose our inexperience so easily!

You can really tell a lot by closely looking at the paper. If the paper has a watermark, you may be able to easily determine when and where it was made. Putting paper up to the light allows us to see some other features. We may see lines

caused by the wires on the mould, or

vatman’s tears, which are water drops from the vatman’s arms, or even more distinct blemishes like thumbprints. Hopefully the paper we make next week will not expose our inexperience so easily!

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.